Manufacturing

Electronics Manufacturing Services (EMS)

Specialized in power electronics

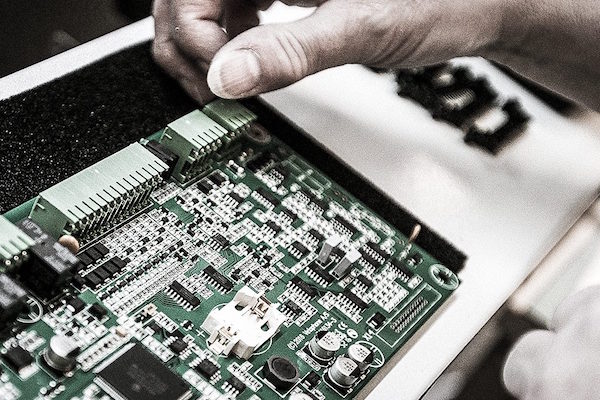

Converdan offers a complete solution for electronics manufacturing – specialized in power electronics. We manage everything from PCBs and SMT component placement to final box build, embedded programming and testing. Our manufacturing capabilities range from custom, low volume applications to multi-year OEM scale production. The build quality meets or exceeds IPC610 standards.

While many firms can make and populate small to medium size PCBs, Converdan is able to manufacture large boards and assemblies with heavy power components, requiring first-class competency in mechanical factors, environmental, thermal and safety considerations. The machinery and test equipment in our assembly shops are state-of-the-art, and we invest in our people just as much as our equipment.

Converdan has helped clients to success by manufacturing:

- Low voltage/power traction converters

- Battery chargers

- Wind turbine converters

- Fuel cell converters

- Stepper-motor controllers

- Welding, plasma & corona inverters

- Special purpose DC/DC

- UPS - Uninterruptable Power Supply

- PFC - Power Factor Correction front-ends

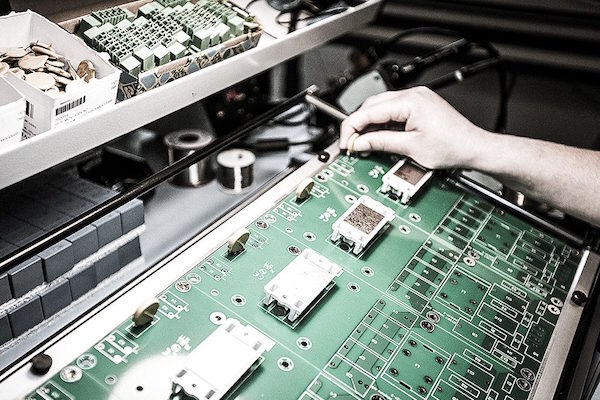

PCB Assembly

Circuit board assembly

The heart of the Converdan manufacturing facility is our PCB assembly shop. We have invested in state-of-the-art machinery and operator training in recent years, enabling us to handle boards from 25×25 mm and a few grams up to heavy power boards weighing several kg. The build quality meets or exceeds IPC610 standards

- Solder paste JET-printing

- SMD assembly of components from 100 x 150 mm down to size 0201

- Vapour Phase soldering

- THT assembly

- Press-fit of power modules and power connectors

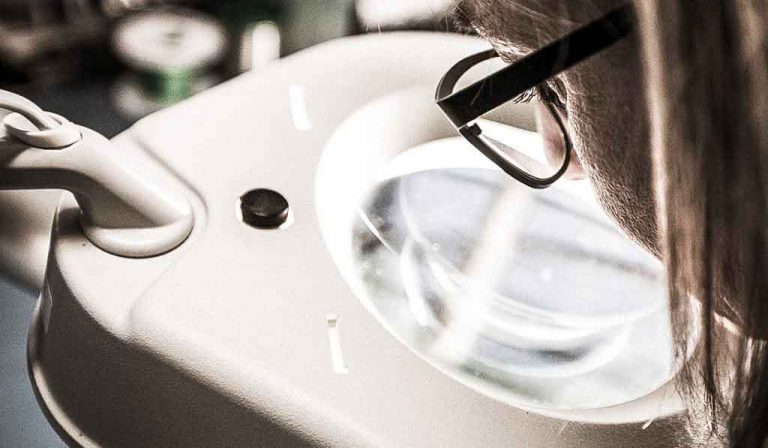

- Optical inspection

- Programming of embedded software

- End Of Line testing of assembled boards

- Conformal coating

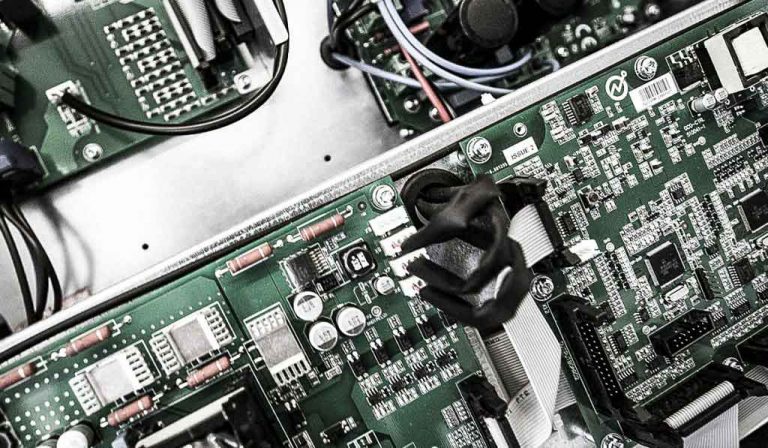

Box-Build Assembly

Building first class products

We have a dedicated production area for our box build and assembly activities. For large scale and repetitive deliveries, we often arrange a manufacturing cell dedicated to your product. Smaller series deliveries are handled equally well in our flexible set-up.

Having worked with power electronics at all power levels, our staff have accumulated many years’ experience in producing high quality power electronics. They have extensive experience and skills in tricky areas of power module mounting methods, heatsink surface finish requirements, thermal interface materials, correct contact pressure and torque settings etc.

Converdan´s Box Build Assembly Services include

- Sub-level product assembly

- Product assembly

- System level assembly

- Testing, including functional, final and burn-in

- Software loading and product configuration

- Warehousing, order fulfillment and traceability

- Packaging and labelling (including bar coding)

- Aftermarket service and factory repairs of Converdan built products

Panel Shop

The power of control

Converdan designs and manufactures control panels for a variety of applications from simple motor starters to more complex controls with many I/O ports and several motor drives or power supplies on-board.

Converdan have ABB and Schneider as preferred component suppliers but can build with other industrial components you have come to rely on. With all of the assembly done in-house, each panel can leave the shop with UL conformity certification and unique identification number.

We have experience from projects in the following areas, among others:

- Industrial machinery

- Off-shore

- Switch gear

- Electric utility grid

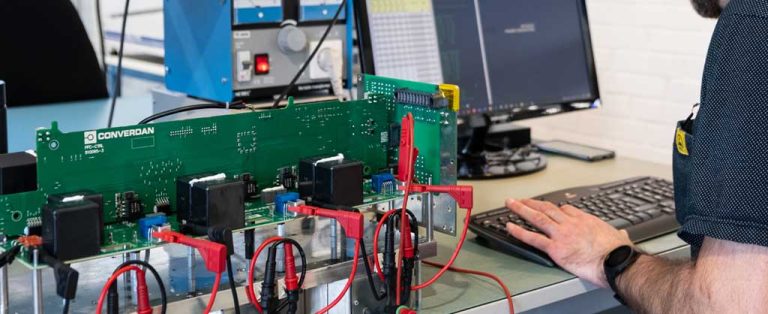

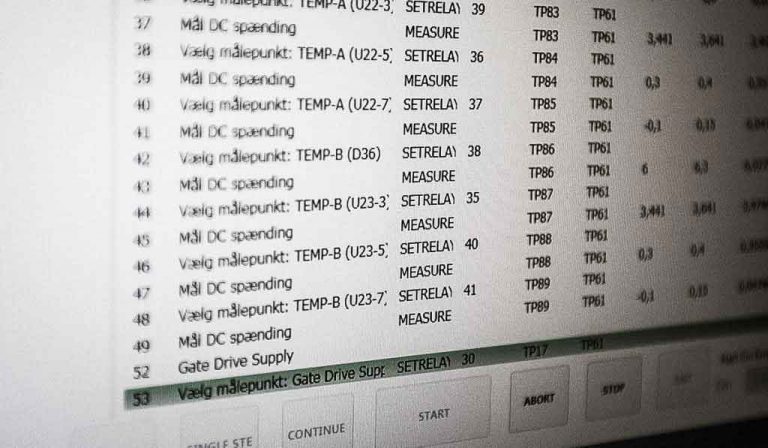

Test & Burn-In

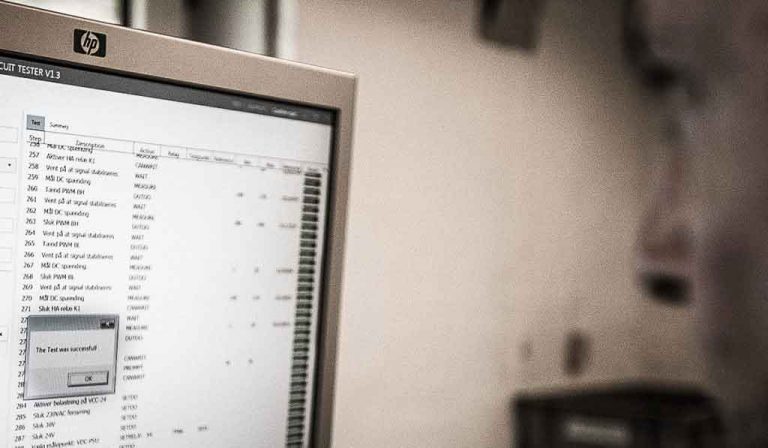

Comprehensive test – made easy

With the Converdan automated test equipment for full load and burn-in tests, savings on custom-made test equipment can be high, especially for low to medium volume productions. Even one-off or prototype products can often undergo a complete production test cycle without our customers making investments in their own costly equipment and training of operators and technicians.

Quality control

Excellence in quality and reliability is our primary goal. We believe it is more efficient to prevent defects from occurring in advance than correcting them afterwards. Quality control has our full attention in all phases, from design evaluation, through material procurement, in process inspection, during the manufacturing cycle, product test, shipping and field reliability tracking.

Repair & Rework

After-sales support

To support your after-sales activities, Converdan can offer repair, rework, remanufacture, upgrade and modification services for your products.

Whether you have a damaged unit out in the field, or have an entire batch of product that needs upgrading to the latest revision, we are able to offer repair and rework agreements to meet your supply chain needs.

Converdan’s repair and rework services include all of our other manufacturing services and all repairs are logged along with a repair protocol.